Additive Manufacturing

When it comes to additive manufacturing, most people think of small tabletop plastic printers that are used for prototyping applications. Only recently has additive manufacturing become a viable and scalable technology available for large scale manufacturing. Now that it is finding a place in industry, the technology is growing and expanding rapidly. Currently, additive manufacturing involving metals covers eight different approaches which can be broken down into sixteen discrete applied technologies. Before industry can take full advantage of these opportunities, someone must evaluate where 3D printing is able to reliably replace or enhance existing manufacturing processes. At the OMIC R&D Additive Innovation Center, we de-risk the choice of equipment for manufacturers and help them identify the best technology to meet their production needs and qualifications.

Researchers

Kyle McGann

Manufacturing Solutions Researcher

Trent LaMont

Manufacturing Solutions Researcher

Sierra Repp

Associate Manufacturing Solutions Researcher

2024

Will Watts

Associate Manufacturing Solutions Researcher

2024

Dave Eames

Associate Manufacturing Solutions Researcher

Dr. Chuankai Song

Research Associate

2024

Dr. Devyn Duryea

Research Associate

Equipment

Impossible Object CBAM25

Coming Soon!

The Impossible Objects tool is a carbon fiber roll-based sheet lamination machine, which allows for very fast printing.

Capabilities include printing Carbon Fiber Nylon 12, Carbon Fiber PEEK, Fiberglass Nylon 12, Fiberglass PEEK and more.

Stay tuned for more details!

GEFERTEC ARC605

The arc series combines the technically mature and proven arc-welding method with 5 motion axis. This offers high deposition rates and part complexity not available through other methods.

Supported by Tier 2 Member GEFERTEC.

TECHNICAL SPECIFICATIONS

Ability to print and material that can be drawn into a wire. OMIC R&D has printed:

- Aluminum Magnesium Alloy (AlMg4)

- Titanium (Ti6Al4V Grade 5)

- Titanium (Ti-5553)

- Stainless (15-5 PH)

- Steel (80S-B2)

- Inconel 625 (NiCr22Mo9Nb)

ExOne 25PRO

The X1 25PRO is an industrial metal 3D printer produced by ExOne (now a part of the Desktop Metal Group). The X1 25PRO was released in 2019 and uses Binder Jetting 3D printing technology.

TECHNICAL SPECIFICATIONS

- Build volume of 400 x 250 x 250 mm

- Non-inerted environment

- Capable of printing non-reactive metals, ceramics, sand

- Used in conjunction with sintering processes (see Elnik information)

Renishaw AM 500S Flex

The RenAM 500s Flex is a laser powder bed fusion machine capable of quick material changeovers, allowing for adaptability into a production aligned system. The 500S Flex utilizes an external sieving process and features a single laser, with the option of adding up to a total of four lasers.

TECHNICAL SPECIFICATIONS

- Build volume of 250mm x 250mm x 350mm

- 500 watt laser

- Fully inerted environment

- Capable of printing reactive and non-reactive metals that are weldable

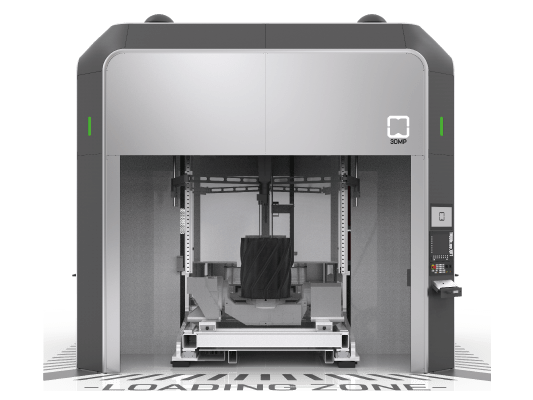

DMG MORI Lasertec 4300

The DMG MORI Lasertec 4300 is a hybrid manufacturing machine with a turn mill form factor, making it unique in its ability to fully build up and finish parts in a single platform. The Lasertec 4300 utilizes a blown powder DED approach to perform the additive process, while also machining with a traditional turn mill process to accomplish machining.

Consigned by Tier 1 member DMG MORI.

Quintus QIH 48

The Quintus QIH 48 URC/URQ is a Hot Isostatic Press (HIP), and is the largest HIP vessel available in a university setting within the United States. The Quintus QIH 48 is unique in that it allows for additively created parts to be fully densified, allowing for the part to be compared to a traditionally machined part. The tool is integral to additive manufacturing.

TECHNICAL SPECIFICATIONS

- Maximum Temperature: 2500 F

- Maximum Pressure: 31K PSI

- Vessel Size: 14″ diameter x 40″ height

- The Quintus QIH 48 has Quintus’ Puris Cycle installed, making it the largest installation of this cycle within the United States. This gives the machine the capability to process titanium alloys without producing alpha-casing, and reduce oxidation on nickel-based alloys.

- URC (Uniform Rapid Cooling) is a cooling process used to achieve uniform cooling rates of up to 200 C per minute.

- URQ (Uniform Rapid Quenching) is a gas quenching process capable of cooling at rates of 1000 C per minute. This process allows for full heat treatment cycles to be performed without the need to remove the part from the HIP.

ELNIK 3025T

ELNIK’s refractory metal series furnaces are state of the art. Processing inside a Double Walled Gas Tight TZM retort with a calibrated gas management system and using a partial pressure vacuum environment offers the best parameters to perform debinding and sintering.

The MIM 3000 series furnace is loaded with automatic functions to allow more uptime on the equipment.

TECHNICAL SPECIFICATIONS

Chamber Dimensions: Lengh 14”, Width 14”, Height 24”

Max Temperature: 160o C (2912 F)

Pressure: 10-7 millibar

Formlabs 3B 3D Printer

The Formlabs 3B 3D Printer is a resin SLA printer capable of achieving high part complexity and accuracy.