Subtractive Manufacturing

Subtractive manufacturing, also referred to as traditional machining, has been the mainstay of production for the last 200 years. In its simplest form, it is taking a piece of metal and removing material until all that is left is the finished part. Of course, subtractive manufacturing today is very high tech. No matter the material or the manufacturing process used in subtractive manufacturing or machining, OMIC R&D has the capability to help you overcome current challenges you are experiencing in your machining production and help you take advantage of your company’s next opportunity. OMIC R&D possesses a wide range of cutting edge five-axis mills, turning machines, and access to some of the worlds best cutting tool manufacturers. When you come to OMIC R&D, you aren’t stuck in the back seat. OMIC R&D will collaborate with you to find a solution that works for your needs.

Researchers

Cody Apple

Senior Machining Solutions Researcher

Taylor Schaming

Associate Manufacturing Solutions Researcher

Pablo Jimenez-Arenas

Machine Operator / Research Assistant

John Timmerman

Machine Operator/Research Assistant

Equipment

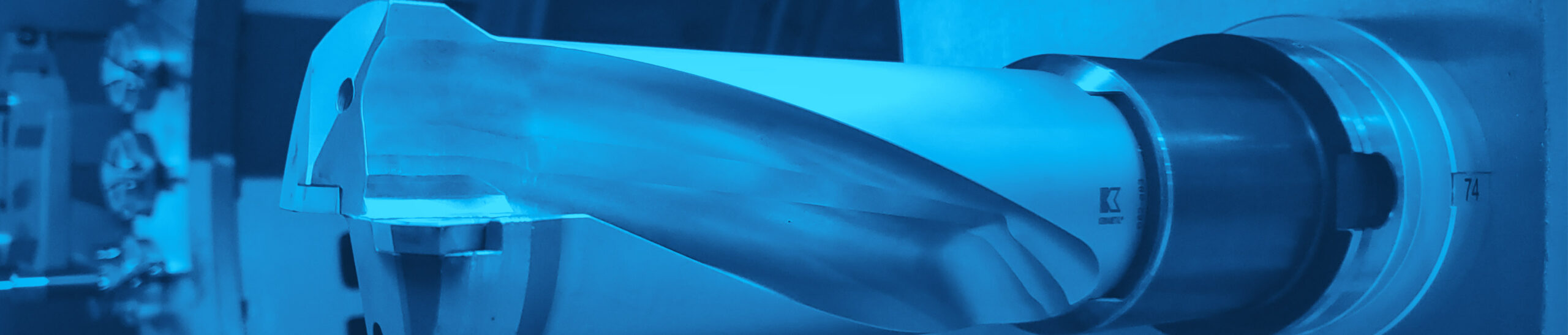

WFL M50

The 5-axis MILLTURN combines all machining and measuring operations into a single complete machining center. The turning-boring-milling unit with gearbox guarantees unparalleled cutting performance with the highest level of precision.

Consigned by Tier 1 member WFL.

Technical Specifications:

- 3000mm maximum cut length

- 500mm maximum turning diameter

- 54kW turning spindle power

- 2000Nm turning spindle torque

- 2500 rpm max turning spindle speed

- 33 kW milling spindle power

- 284Nm milling spindle torque

- 5000 rpm max milling spindle speed

- HSK100 tool interface

Okuma Genos M560V

The 3-axis Okuma vertical mill boasts a highly rigid, thermally stable construction that allows this vertical machining center to withstand thermal deformation resulting in reduced thermal growth and improved machining performance. It can handle a variety of materials from titanium to aluminum, and does so without sacrificing finish quality or productivity.

Caron Engineering TMAC, Auto Comp, Tool Connect and Smart Light installed from Tier 2 member Caron Engineering.

Absolent Filtration system consigned by Tier 2 member Absolent.

Technical Specifications:

- 41.34” x 22.05” x 18.11” maximum machining volume

- 15,000 rpm maximum spindle speed

- 30hp milling spindle power

- 1000 psi available coolant pressure with automatic flow rate adjusting

Doosan DVF5000

The DVF Series is the newest line of 5-axis machining centers from Doosan Machine Tools. Built with cutting-edge technology, ergonomic accessibility, and an automation-ready framework, the DVF delivers excellent performance. The DVF features a combined pivoting and rotary table to provide optimum access to all 5 axes, while maintaining rigid spindle support for reduced vibration.

Technical Specifications:

- 24.6” x 17.7” x 15.7” travel distances

- 19.7 in diameter table size

- 60 BIG PLUS CAT 40 tool chain

- 18,000 rpm spindle

- 30 hp milling spindle power torque

- 87 ft-lbs milling spindle torque

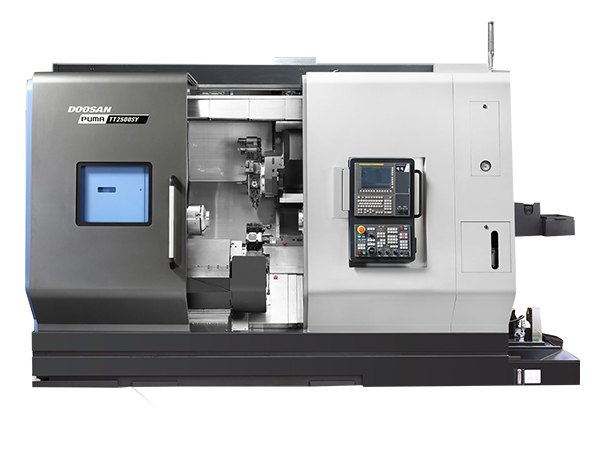

Doosan PUMA TT2500 SY

The 7-axis Doosan lathe is a high-performance turning center featuring first and second spindles that have the same power and capacity, with upper & lower turrets on the grounded box type bed. It is capable of simultaneous machining on two faces with both spindles and turrets and virtual realization of y-axis function which can double productivity.

Caron Engineering TMAC installed from Tier 2 member Caron Engineering.

Technical Specifications:

- 13.8 in maximum cut length

- 15.4 in maximum turning diameter

- 34.9 hp turning spindle power

- 3500 rpm max turning spindle speed

- 10.1 hp milling spindle power

- 4000 rpm max turning spindle speed

- 1000 psi available coolant pressure with automatic flow rate adjusting

- Big Plus CAT40 shank

ANCA TX7 Linear

The ANCA TX7 is a premium grinding machine, aimed at the most demanding and diverse applications. The TX Linear range is the new industry benchmark for production grinding and machining of cutting tools. With a large working envelope and powerful grinding spindle, the TX Linear range will deliver precision and productivity across the widest range of applications.

Technical Specifications:

- 49 hp Big Plus 40 direct drive spindle

- 2 wheel changer pack for wheels to 8”

- Tool lengths up to 16” long and 12” diameter

Sugino JCC 603 ROBO

The JCC 603 ROBO is the world’s first MAX 245MPa ultrahigh-pressure water jet enabling deburring of all material types including aluminum, steel, titanium and inconel alloys. A high-efficiency washing machine capable of transferring, washing and drying all in a single unit. The use of a highly rigid robotic hand helps reduce cycle time and space on the factory floor.

consigned by Tier 2 member Sugino.

Technical Specifications:

- 245MPa x 4L/min jet

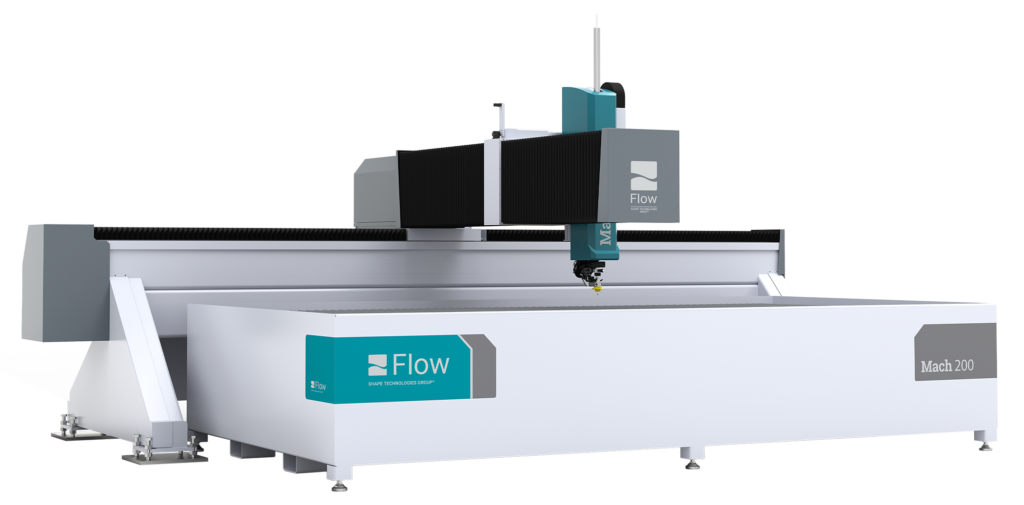

Flow International Mach 200 Pivot+

The FLOW Mach 200 Pivot+ is a waterjet cutting machine renowned for its high precision and versatility. It utilizes a high-pressure water and abrasive mixture to cut through various materials, including metals, composites, and stone.

Waterjet machines like the Mach 200 Pivot+ are known for their material flexibility, as they can cut different materials without heat distortion. This makes them suitable for sensitive materials and allows for the creation of intricate shapes and designs.

PERFORMANCE

Bed Size = 10 ft x 6.5ft

Pump Pressure = 60,000 psi

Grit = 80 grit silica

Max Rapid Traverse = 400 in/min

Linear Accuracy = +/- 0.003 in/3 ft

Repeatability = 0.0015 in

Kern OPF100 250w Laser Cutter

The OptiFlex is an industrial large format laser cutting system. The HyperDual motion package debuts on the OptiFlex and is setting the standard for large format laser cutting and engraving across the world.

This improved motion system features a rack and pinion design and powerful servo motors at each side of the laser table. The X axis has also been upgraded with twin linear rails and a thicker steel reinforced belt. An advanced safety package can be added to the OptiFlex for high traffic working environments.

PERFORMANCE

Laser Classification = Class 4 CO2 Laser

Laser Wattage = 100 – 650 watts

Positioning Accuracy = +/- 0.002 in/ft

Repeatability = +/- 0.0005 in/ft

Work Area = 52” x 50”

WORKPIECE MATERIALS = Acrylic, Mild Steel, Stainless Steel,

Aluminum, Brass, Wood, Foam,

Leather, Stone, Rubber, Textiles