Inspection

In the realm of advanced manufacturing, inspection plays a pivotal role in ensuring that products meet stringent quality standards, which is essential for maintaining competitiveness and customer satisfaction within industry. At OMIC R&D, our focus on inspection technologies is not just about adhering to standards; it’s about pushing the boundaries of what’s possible in quality assurance. We leverage cutting-edge inspection methodologies, including advanced imaging, laser scanning, and robotic inspection systems, to provide detailed insights into product quality that were previously unimaginable.

Equipment

ATOS 5 Scanbox 6130

Consigned by member Capture 3D.

The ATOS series of high quality industrial structured blue light 3D scanners provide precision scans with detailed resolution at high speeds. ATOS is a type of a coordinate measuring machine (CMM) that utilizes optical non-contact technology to capture millions of accurate points in a single fast scan. Developed for industrial use, the ATOS 5 delivers high-precision data in a short measuring time even under harsh conditions. The full-field 3D measuring data allows comprehensive process and quality control, visualizing hidden errors and thus speeding up production processes. The right combination of hardware and software allows for safe integration of 3D metrology into production.

TECHNICAL SPECIFICATIONS:

- LED light source

- 12 million points per scan

- 880mm working distance

- dimensional and GD&T inspection

- robotic integration or mobile with tripod

MTS Landmark 22KIP Frame

The MTS Landmark 22KIP Frame is a load station capable of performing tensile, compressive, and low to medium cycle fatigue testing. This is a reliable machine which allows for long term testing capabilities with the option to add many additional testing components.

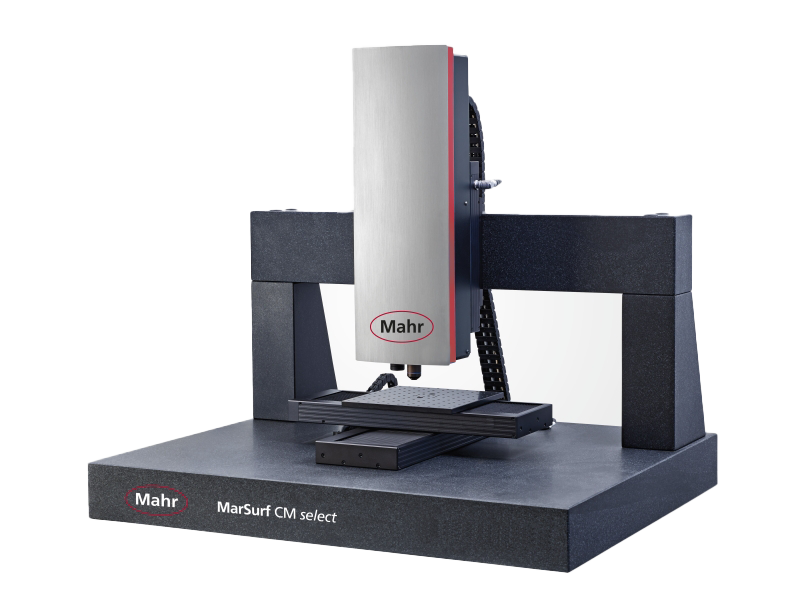

Wenzel LH1210 CMM

The Wenzel is a coordinate measurement machine with the newest generation air bearings capable of providing the highest performance in 3D measurement, integration with Renishaw heads, and keeping up with technology as its being developed, including contact and non-contact inspection methods.

Technical Specifications:

- 1200mm x 3000mm x 1000mm measuring range

- Renishaw REVO 2 head

- Ability to perform constant contact measurement

- Ability to inspect surface roughness

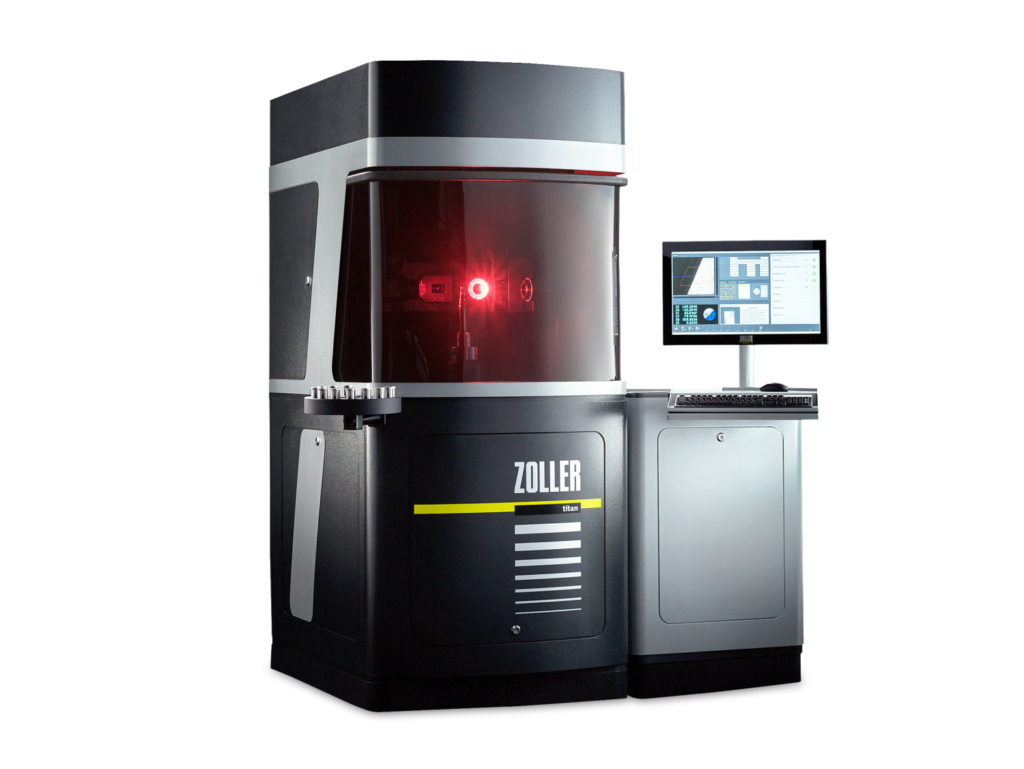

ZOLLER Titan

The titan is a high-end inspection and measuring machine with unrivaled flexibility and precision in the measurement of cutting tools. Seven CNC-controlled axes measure any type of machine tool with high precision and full automation.

Technical Specifications:

- 260mm diam x 400mm length operating envelope

- Hundreds of measuring programs including the ability to measure edge hone

- Tailstock center for measuring of tools between centers