Research

OMIC R&D boasts one of the most advanced Additive and Subtractive R&D centers in the world

We are constantly updating our capabilities with the addition of a one-of-a-kind Additive Innovation Center, which will contain all seven primary additive manufacturing technologies. Having a diverse range of technologies allows us to be nationally unique, and we work with you to match your challenges to the technology that best aligns with your product. OMIC R&D only engages in applied research, which means the R&D we conduct can be directly implemented to the production line.

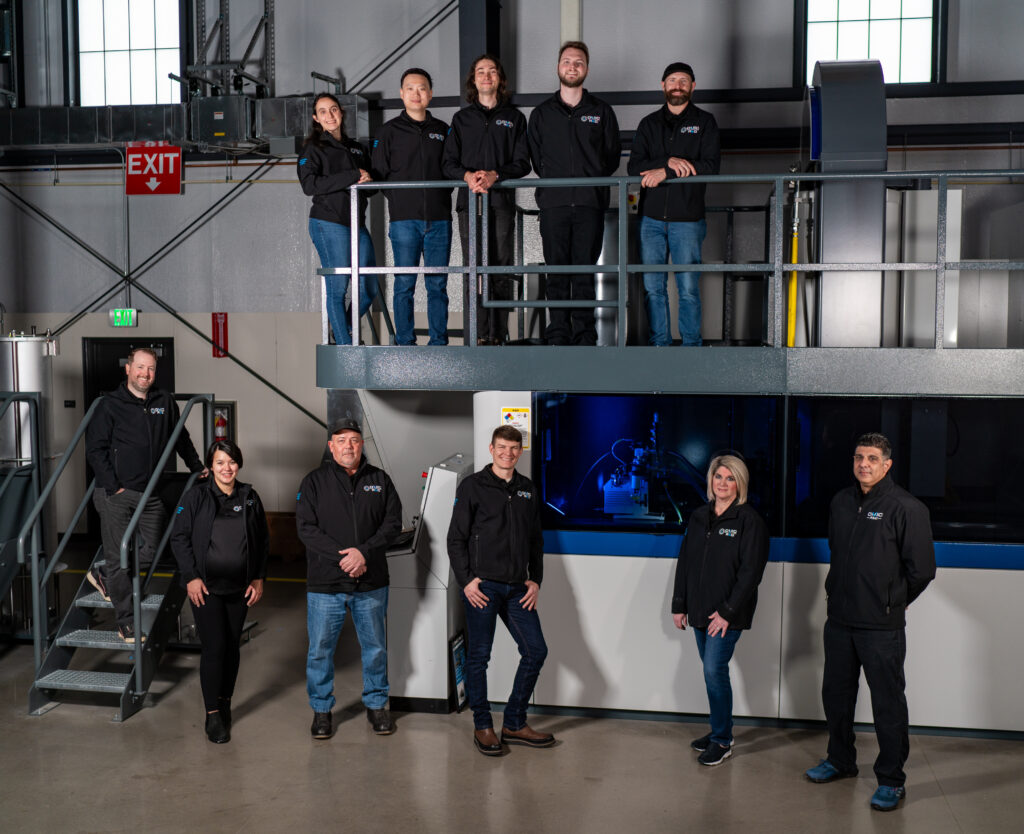

Our researchers

At the beginning and end of each day, the research we do is only as good as the people we have conducting it. OMIC R&D is proud of the innovative culture we have developed, and that culture is maintained by people who love to innovate, collaborate, and who see roadblocks as an opportunity to find another path. Our on-site researchers have years of hands-on industry experience and are not bound by past practices. Everything we do is being done for the first time. In addition, we have access to university researchers who are respected luminaries in their fields and who appreciate seeing companies apply their cutting-edge research in the production line.

Cody Apple

Senior Machining Solutions Researcher

Kyle McGann

Manufacturing Solutions Researcher

Taylor Schaming

Associate Manufacturing Solutions Researcher

Trent LaMont

Manufacturing Solutions Researcher

Sierra Repp

Associate Manufacturing Solutions Researcher

2024

Will Watts

Associate Manufacturing Solutions Researcher

2024

Dave Eames

Associate Manufacturing Solutions Researcher

Dr. Chuankai Song

Research Associate

2024

Pablo Jimenez-Arenas

Machine Operator / Research Assistant

Dr. Devyn Duryea

Research Associate

John Timmerman

Machine Operator/Research Assistant

Our Facilities

OMIC R&D has some of the most advanced manufacturing and inspection machines from around the globe. Our range of mills, lathes, millturns, grinders, metrology equipment, metal 3d printers, and cobots allows us to transform nearly any manufacturing-based development into innovative means, methods and technologies.

OMIC R&D members provide several of the machines currently conducting research at our campus. These machines are on rotating consignment, and the sale of machines in our facilities makes room for the latest version of that equipment. We demonstrate the benefits of these advanced machine tools with you, on your products, to de-risk your investment.